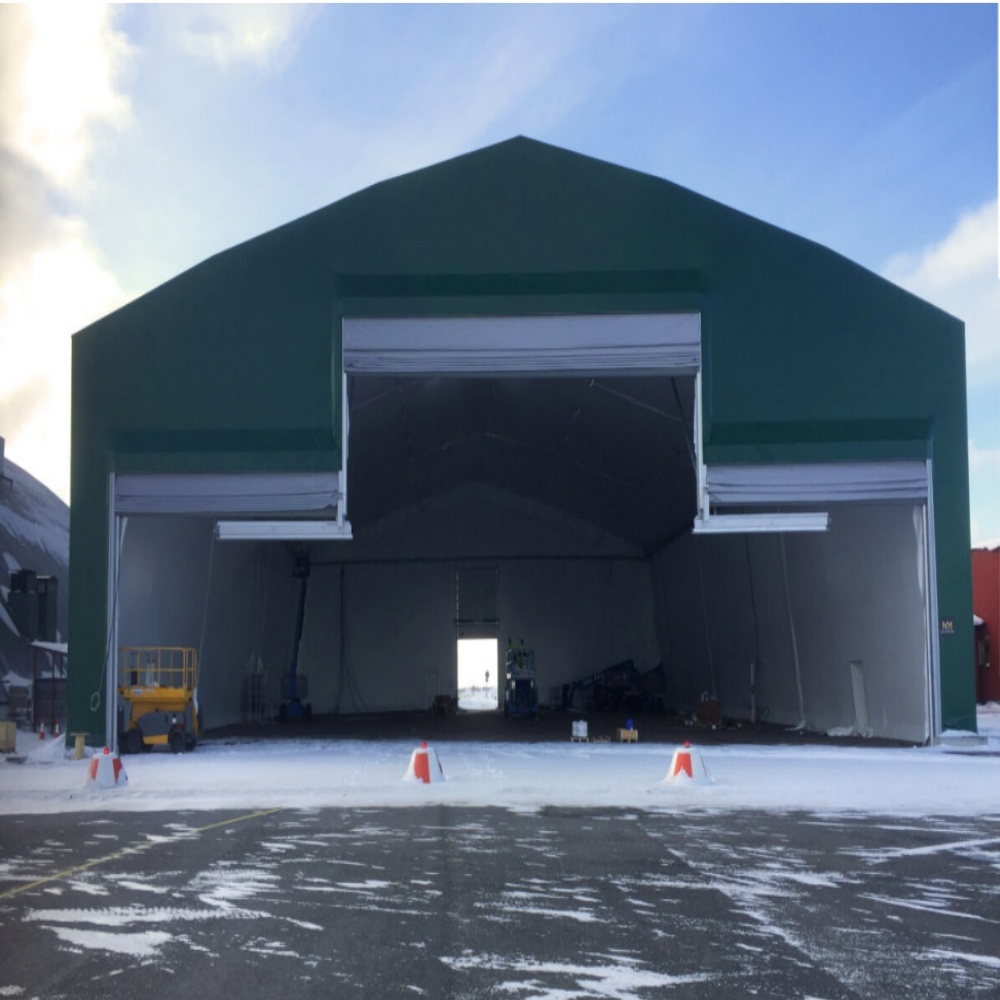

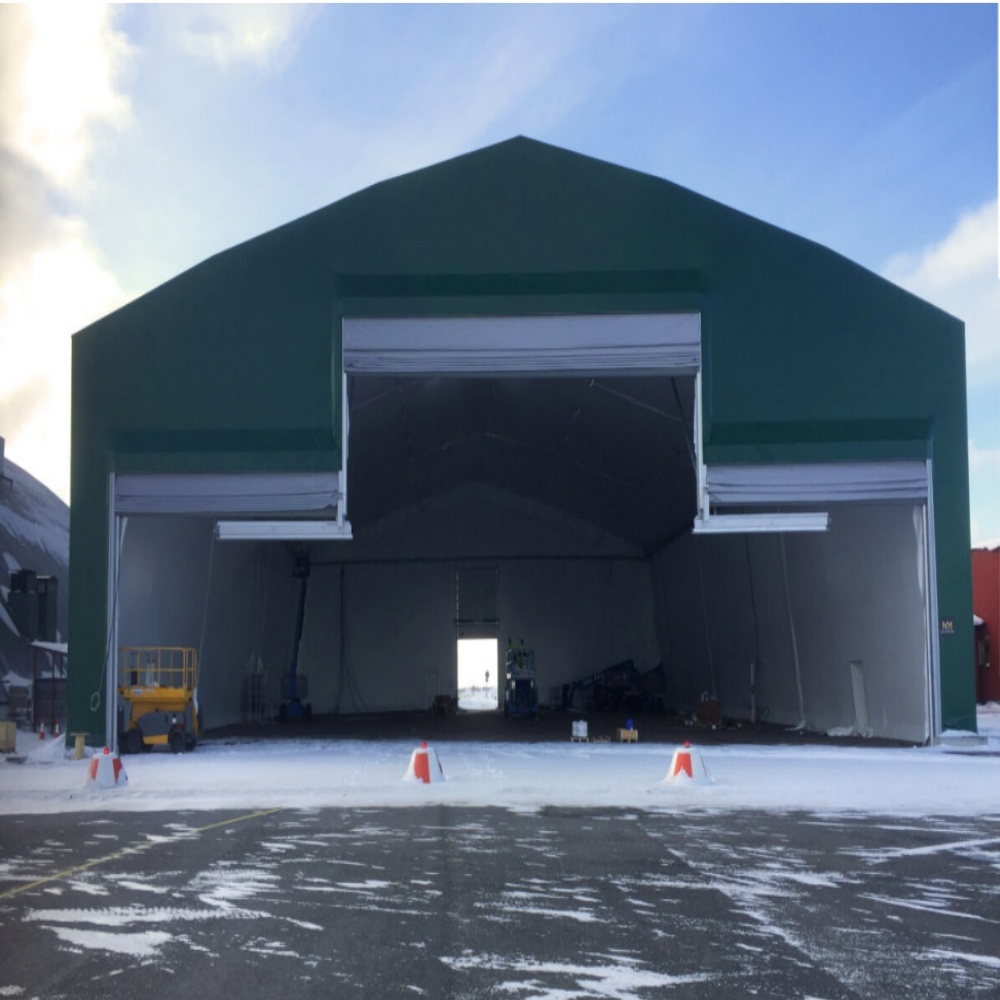

Hot-rolled galvanized H-shaped steel structure prefabricated hangar

metal building

Strength and durability: The steel used in the steel structure

hangar has excellent strength and durability. In the face of bad

weather, such as strong winds, heavy rains and temperature

differences, it can respond stably. Its excellent

strength-to-weight ratio ensures that the hangar can support a

large space, withstand the parking weight of the aircraft and the

dynamic load caused by frequent operation, and provide a

long-lasting and reliable shelter for the aircraft.

Efficient construction: The steel structure of the hangar can be

pre-fabricated in the factory and then transported to the site for

quick assembly. Compared with the traditional construction process,

this method greatly shortens the construction period, allows the

hangar to be put into use faster, reduces the overall time cost of

the project, and improves the efficiency of airport operation

preparation.

Design flexibility: The excellent properties of steel give hangars

great flexibility. Designers can shape the steel structure into a

variety of shapes according to the needs of different aircraft

models and operating processes, whether it is a tall and open

single-span space or a composite structure with clear functional

partitions, it can be easily realized, creating a building

appearance with both practicality and modern aesthetics.

Significant long-term economic benefits: Although the initial

construction investment of the steel structure hangar is relatively

high, it has a cost advantage in the long run. The steel is

corrosion-resistant, insect-proof, with little daily maintenance

workload, and the service life is far beyond that of ordinary

building materials, effectively reducing follow-up maintenance and

replacement costs and ensuring long-term stable operation.

Material Category | Specific Material | Specification | Quantity | Purpose |

Main Structure Steel | H-shaped Steel | Section dimensions determined by design calculation, such as common

400mm×200mm×8mm×13mm, etc. | Determined according to the scale and structural design of the

aircraft hangar | Form the main load-bearing frame of the aircraft hangar, such as

steel columns and steel beams |

| Channel Steel | For example, 10# channel steel (height 100mm, leg width 48mm, waist

thickness 5.3mm) | Several | Used for supporting and connecting part of the structure to enhance

overall stability |

| Angle Steel | Common ∠50×50×5mm, etc. | Appropriate amount | Used for joint connection, stiffening and other parts |

| Round Steel | Such as diameter 20mm, etc. | As required | Can be used as auxiliary structural components such as tie rods |

Roof Materials | Color Steel Plate | Thickness is generally 0.5mm - 0.8mm, width is about 1m | Calculated according to the roof area | As the roof covering layer, playing the role of waterproofing and

heat preservation |

| Thermal Insulation Cotton | Thickness 50mm - 100mm, bulk density 12kg/m³ - 16kg/m³ | Determined according to the roof area and heat preservation

requirements | Filled in the roof structure to improve the heat insulation

performance |

| Self-tapping Screws | Diameter 4.8mm - 6.3mm, length determined according to the

thickness of the plate and connection requirements | A large number | Used to fix color steel plates and related accessories |

Wall Materials | Color Steel Plate | Similar to the specifications of the roof color steel plate | Calculated according to the wall area | Form the walls of the aircraft hangar |

| Thermal Insulation Cotton | The same as the roof thermal insulation cotton | Determined according to the wall area and heat preservation

requirements | Wall insulation |

| Doors and Windows | Aluminum alloy doors and windows or steel doors and windows | Customized according to the design size | As required |

| Sealing Rubber Strips | Adapt to the size of doors and windows | Appropriate amount | Used for door and window sealing to prevent rainwater leakage and

air penetration |

Connection Materials | High-strength Bolts | M16 - M30 and other specifications | Calculated according to the number of connection nodes | Used for the connection of the main frame of the steel structure to

ensure the connection strength |

| Ordinary Bolts | M8 - M12 and other specifications | A large number | Used for auxiliary connection and fixing of some components |

| Welding Materials | Such as E4303 welding electrodes (used for welding Q235 steel) | Determined according to the welding workload | Used for steel welding connection |

Fireproof Materials | Fireproof Coating | Thin or thick type, selected according to the fire protection grade

requirements | Calculated according to the surface area of the steel structure | Painted on the surface of the steel structure to improve fire

protection performance |

Product Advantages:

Superior structural performance: steel has high strength, good

toughness, can withstand large loads, can resist strong winds,

earthquakes and other natural disasters, and ensure the safety of

airport buildings under extreme conditions, such as in

earthquake-prone areas, the seismic performance of steel structure

airports is particularly prominent.

Efficient space utilization: The steel structure can achieve a

large span of space, which can meet the needs of airport terminals,

hangars, etc. for open space, and is convenient for flexible

division of functional areas, improving space utilization,

providing a comfortable waiting environment for passengers, and

also conducive to aircraft parking, maintenance and other

operations.

Fast construction speed: The steel structure components are mostly

prefabricated in the factory, and then transported to the site for

installation, which can effectively reduce the on-site construction

time and workload, speed up the construction progress of the

airport, so that the airport can be put into use earlier and reduce

the construction cost.

Our advantages

★Superior material performance: The steel we produce has high

strength and good toughness, and the steel structure products made

of it are of reliable quality and can withstand large loads, such

as in large industrial plants, which can easily carry heavy

equipment.

★Strict quality control: The factory has established a standardized

quality management process, from raw material procurement to

component processing and assembly, all links are strictly

controlled to ensure stable product quality and improve yield.

★Technological innovation promotion: Continuously introduce new

technologies and new equipment, such as advanced cutting and

welding equipment and information management systems, to improve

the degree of production automation, improve production efficiency

and quality stability.

★Flexible space design: It can realize large-span and complex space

structure design to meet different building functions and space

needs, such as airport terminals, large stadiums and other open

space buildings.

Choosing our steel structure storage products is to choose

professionalism, quality, efficiency and value. We look forward to

working with you to create exceptional construction projects.

Company Profile

China CT Steel Structure Co.,Ltd of BY GROUP is a comprehensive

industrial group integrating for steel structure design,

manufacture and installation. We have estabulished over 21

years.The factory covers an area of 30 hectares.

Main products: steel structural warehouse, workshop, high rise

steel building, school, hotel,office building, exhibition building,

show room, shopping mall, stadium,Agricultural project

(stable/cattle barn, poultry house,pig house), car parking,

hangar,shed,storage room, prefab house, container house, Sandwich

panel,corrugated steel sheet, C&Z sec- tion steel, door and

windows and cranes.

Packing: we pack all the parts on the steel pallet and push into

the container when clients received they can pulling them out

within half an hour. It can help our clients to save a lot of time

and labor cost during unloading.

Container loading; We will supply the materials list, the packing

lists based on the contents we loaded into container. Showing the

quantity, part no. length, container no, seal no.after finishing

the container loading.

"Quality and service first "is our company's development goals. We

hope we will develop together and win more projects together!

Packaging & Shipping

1. All standard components are packed in plywood box.

2. All steel structure weld components are packed with blanket or

bubble-wrap to avoid scratch during loading and unloading.

3. All steel structure are packed in steel pallet together into

container, much save loading and unloading time, labor cost.

4. All sandwich panel are packed in steel pallet.

5. Material components will be made container load plan, also make

regional unloading plan to avoid retransport on site.

6. All equipment pasted with English lable

7. Small equipment will packed in carton or plywood box

FAQ

Q: Are you a factory or trading company?

A: We are a manufacturing factory, we can provide one-stop service

for customers. You can get the best service and competitive prices.

Q: How can I get a quote for a project?

A: You can contact us via email, phone, Trade Messenger, WhatsApp,

Skype, Viber, etc., and we will get back to you as soon as

possible.

Q: Do you accept container loading inspections?

A: You are welcome to send inspectors to visit the factory, not

only at the time of loading, but also at any time. If it's not

convenient, we also provide real-time video display.

Q: Do you provide design services?

A: Yes, we can design complete solution drawings according to your

requirements. They use software such as Auto CAD, PKPM, MTS, 3D3S,

etc.

Q: What's the payment terms?

A: Payment terms: T/T, L/C, other payment methods can be negotiable

Q: What's the delivery time?

A: The delivery time depends on the order quantity.