Industrial Petrochemical Steel Structure Grid High-rise Building

product Description

structural composition

Frame columns: mainly bear vertical loads and bear vertical and

horizontal loads from beams, equipment, etc.

The cross-section size is determined according to calculation for

hot-rolled or welded wide flange H-section steel. The bottom is

connected to the foundation with anchor bolts, and the top is

connected to the frame beam.

Frame beam: Withstands vertical loads on the floor or platform and

transfers them to the frame columns. H-shaped steel is mostly used

and connected to the frame columns by welding or high-strength

bolts to form rigid or semi-rigid joints.

The beam span is generally 6 - 12 meters, which is determined by

equipment layout and process requirements.

support system Horizontal support: arranged on the plane of the

frame beam, divided into rigidity and flexibility. Rigid supports

such as

crosses and chevron supports resist horizontal wind loads,

earthquake actions and horizontal forces from equipment vibration

and

are transmitted to the foundation; flexible supports use round

steel or steel strands to limit horizontal displacement by

tension.

Vertical support: Located between frame columns to improve the

vertical stability of the frame and prevent out-of-plane

instability of the

frame columns. The form is similar to horizontal support and

together form a stable spatial stress system.

node is connected Connection methods: There are welding,

high-strength bolts, and mixed connection of welding and

high-strength bolts.

Characteristics: Good welding integrity and high rigidity, but it

is difficult to control on-site construction quality, which is

prone to residual

stress and deformation; high-strength bolts are convenient to

construction, removable and reliable under stress;

hybrid connection combines the advantages of the two and is

selected according to the stress characteristics of different

parts.

Product information |

Column and beam | Welding steel or hot-roll steel |

Steel surface treatment | Hot-dip galvanized or painted(all colors we can do) |

Steel grade | Q235,Q345,ASTM,EN10225 |

Purlin and girt | C and Z section steel |

Connection Method | All bolt connection,easy installation |

Wall&Roof | Sandwich panel with EPS or rock wool insulation |

Wall&Roof | Metal sheet with blue red white grey color or customize |

Door | Rolling shutter door or sandwich panel sliding door |

Window | Plastic shutter door or sandwich panel sliding door |

Bolt and nuts | High strength bolt and ordinary bolt |

Design life span | 25 years and 50 years |

Place of origin | Qingdao city, Shandong province, China(Mainland) |

Business type | Manufacture and trading |

Packaging Details | Bunding with pallet or customize |

Product Advantages

High strength and light weight: Steel has higher strength and lower

density. Compared with traditional concrete structures, the dead

weight of steel structural frames is lighter under the same load.

This not only reduces the bearing pressure of the foundation,

reduces the cost and construction difficulty of the foundation

project, but also facilitates transportation and installation. For

example, in some large petrochemical projects, the use of steel

structural frames can greatly reduce the weight of the entire

device, which is particularly important for projects built on soft

soil foundations.

Product Application

Reaction towers: In production processes such as petroleum refining

and chemical synthesis, many reactions need to be carried out at

specific heights and spaces. High-rise steel structural frames are

used to support various reaction towers, such as catalytic cracking

towers in refineries, cracked gas separation towers in ethylene

units, etc. These reaction towers are often of high height, large

diameter, and carry complex chemical reactions and material

transfer processes internally. With its high carrying capacity and

stability, the steel structural frame can provide reliable support

for the reaction tower and ensure the smooth progress of the

reaction. Large-scale equipment support: Large compressors, pumps

and other equipment in petrochemical production usually need to be

installed on a platform at a certain height to facilitate material

transportation, operation and maintenance. The high-rise steel

structure frame can build a multi-story platform structure, and

these equipment can be reasonably arranged at different heights to

achieve smooth connection of the process flow. For example, in

natural gas processing plants, large compressor units are often

installed on second-or three-story platforms supported by steel

structural frames to facilitate pipeline connections and equipment

maintenance.

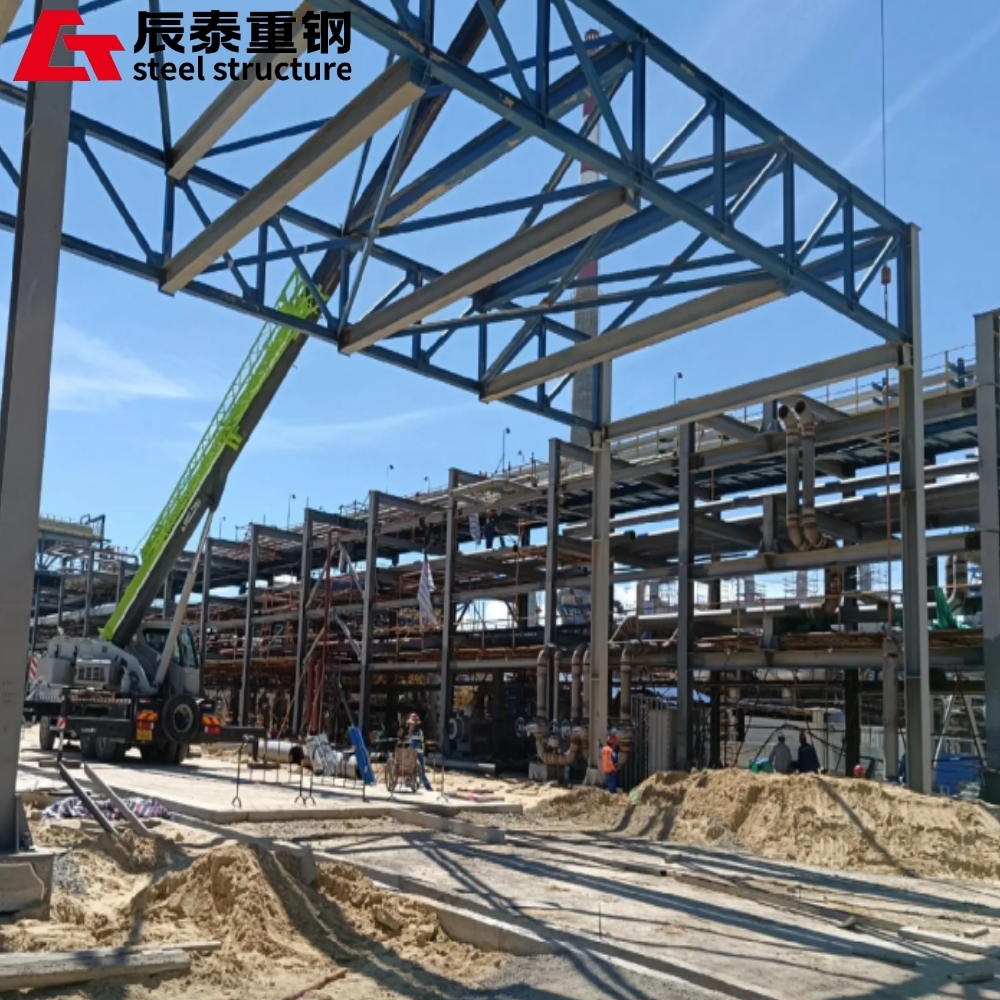

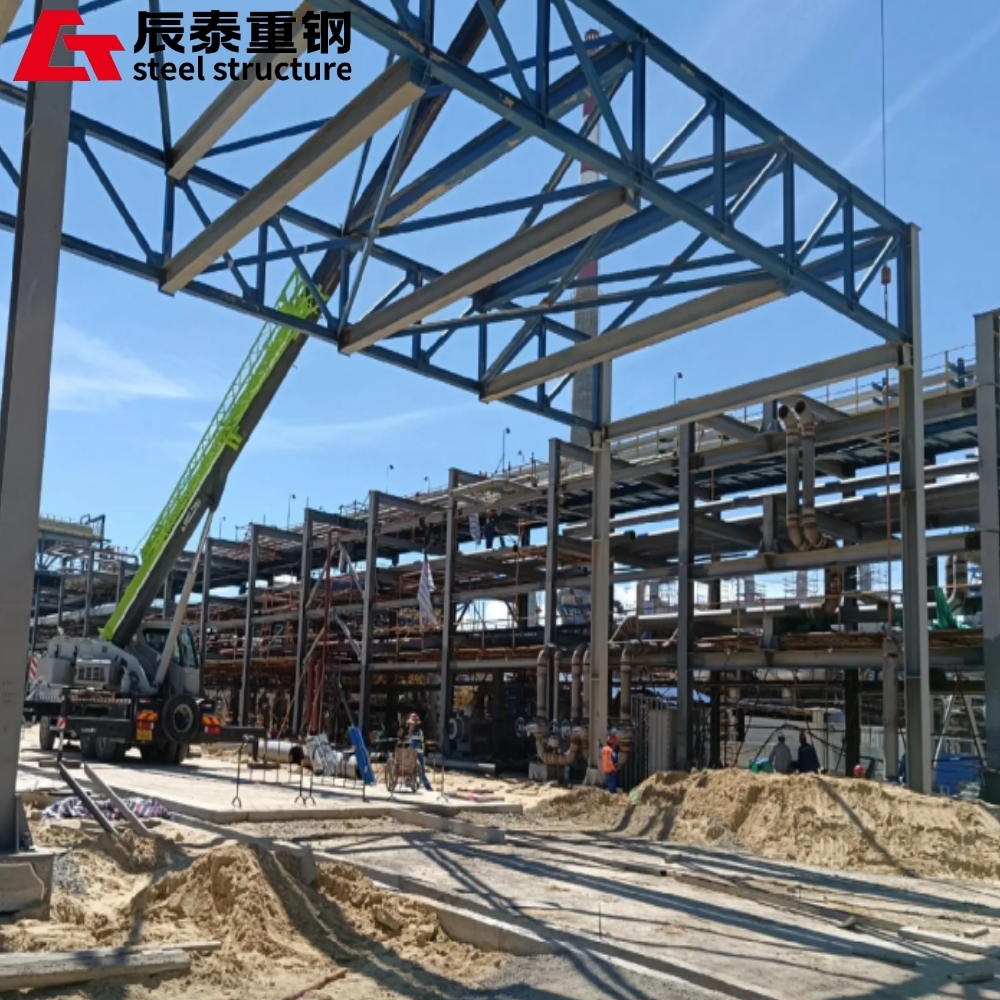

product picture

Company Introduction

China CT Steel Structure Group Co., Ltd. is a comprehensive

industrial group that integrates steel structure research and

development, design, manufacturing, production, and installation.

Since its establishment in 2004, it covers an area of approximately

30 hectares and produces 200000 tons of steel structures annually.

We have over 500 well-trained employees, more than 100 professional

design teams, after-sales service teams, and many advanced

equipment.

The company has 30 steel structure production lines, specializing

in the design, manufacturing, and installation of industrial and

civil buildings such as steel structure factories, warehouses,

high-rise steel structure buildings, office buildings, exhibition

halls, sports halls, parking garages, prefabricated houses, and

agricultural projects. We are committed to providing customers with

innovative solutions that not only meet their expectations, but

also exceed them.

packaging and shipping

FAQ