China Exports Customizable Color Large Span Steel Structutre

Workshop

Product Description:

Steel structure factories have a wide range of applications. In the

machinery manufacturing industry, its spacious space and strong

carrying capacity can meet the installation and operation needs of

large-scale machinery and equipment; in industries with high

production environment requirements such as electronic information

and food processing, steel structure factories can be reasonably

designed and decorated to achieve special production environments

such as cleanliness, constant temperature and humidity; in the

field of warehousing and logistics, the steel structure factory has

the characteristics of large span and large space, which

facilitates the storage and transportation of goods; In addition,

steel structure factories are also often used in many industries

such as automobile manufacturing, chemical industry, and energy,

and have become an important form of building to promote the

development of industrial modernization.

Product Advantages

1.High strength and stability Through precise welding and bolting

techniques, the overall stability and safety of the steel structure

workshop are ensured, allowing it to remain stable in harsh natural

environments.

2.Flexible spatial layout: Steel components are highly

machinability and can flexibly design and build diversified spatial

layouts according to different production processes and functional

requirements. Whether it is a spacious and open space or divided

into multiple different functional areas, the steel structure

factory building can be easily realized, reserving sufficient

transformation space for the company's later production adjustments

and equipment upgrades to adapt to changing production and

operation needs.

3.Strong earthquake and wind resistance:

The steel has good toughness and strong ductility, can withstand

large deformation, and has a seismic fortification intensity of 7 -

9 degrees, suitable for earthquake-prone areas. For example, the

damage rate of steel structures during the Wenchuan earthquake was

much lower than that of concrete structures.

4.Low-carbon, energy-saving, recycling:

The construction process has less pollution, and construction waste

is reduced by 90% compared with traditional processes, which is in

line with the concept of green building.

Product Attributes

| Remark |

| Brace | ordinary, high strength bolt |

| Main frame | H beam |

| Roof &wall | EPS,Rock wool , PU sandwich |

| Insulation panel | EPS,Rock wool , PU sandwich |

| Purlin | C or H section steel purlin |

| Door | Sliding or rolling door |

| Sheet | 0.2mm-0.6mm galvanzied steel sheet |

| Material | Q235B,Q355B China standard steel |

Transport Specifications

| Package Size | 100.00cm * 100.00cm * 100.00cm |

| Package Gross Weight | 100.000kg |

Product Use

1. Heavy industry Machinery manufacturing: For example, machine

tool processing and mining equipment production workshops need to

withstand crane loads (such as bridge cranes of more than 20 tons)

and equipment vibration. Metallurgical and chemical industry: In

high-temperature and high-load environments (such as steel-making

workshops and chemical reaction workshops), structures need to be

resistant to high temperatures and corrosion.

2. Light and precision industries Electronic/food workshop: A clean

environment is required. The steel structure can quickly build a

dust-free workshop, and the color steel plate wall is used to

achieve sealing and dustproof. Logistics warehousing: High

clearance, long-span requirements (such as three-dimensional

warehouses, sorting centers), convenient for forklift operations

and rack installation.

3. special industries Aerospace: Ultra-large factories (such as

aircraft assembly workshops), with a span of more than 100 meters,

meet special processes such as aircraft take-off and landing

simulation. Energy field: For example, wind power equipment

manufacturing workshops and photovoltaic module production lines

require flexible layout and rapid production.

Product Picture

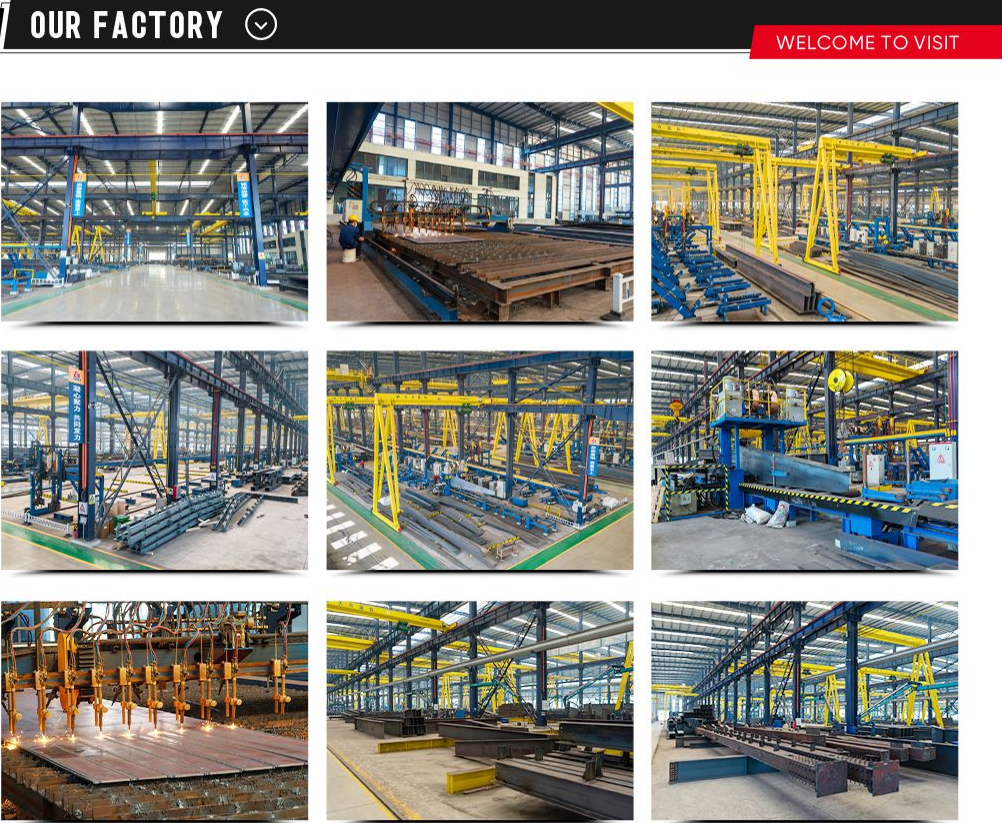

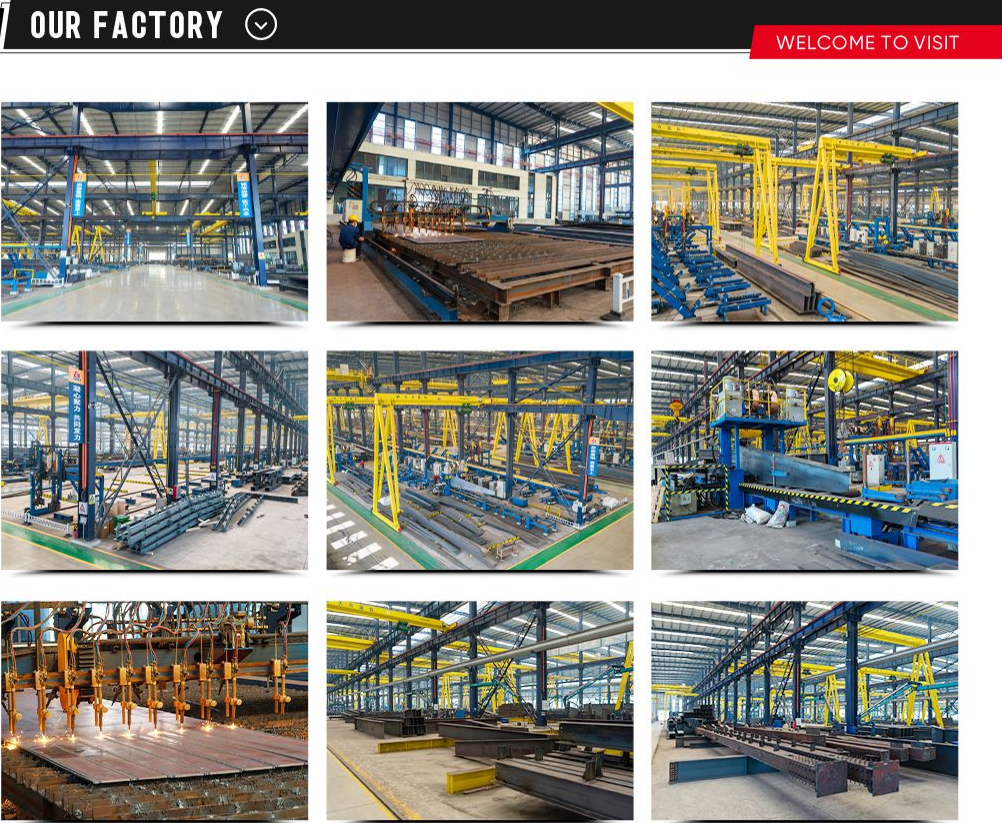

Company Introduction

China CT Steel Structure Group Co., Ltd is a comprehensive

industrial group that integrates steel structure research and

development, design, manufacturing, production, and installation.

Since its establishment in 2004, it coversan area of approximately

300000 square meters and produces 200000 tons of steel structures

annually. We have over 500 well-trained employees, more than 100

professional design teams, after-sales service teams, and many

advanced equipment.

China CT Steel Structure Group Co., Ltd is a comprehensive

industrial group that integrates steel structure research and

development, design, manufacturing, production, and installation.

Since its establishment in 2004, it coversan area of approximately

300000 square meters and produces 200000 tons of steel structures

annually. We have over 500 well-trained employees, more than 100

professional design teams, after-sales service teams, and many

advanced equipment.

The company has 30 steel structure production lines, specializing

in the design, manufacturing, and installation of industrial and

civil buildings such as steel structure factories, warehouses,

high-rise steel structure buildings, office buildings,

exhibition,halls, sports halls, parking garages, prefabricated

houses, and agricultural projects. We are committed to providing

customers with innovative solutions that not only meet their

expectations, but also exceed them.

The quality control measures of steel structure project are as

follows:

1,Strengthen the management of technical personnel

In the construction process of the construction site, the

construction personnel occupy the main position in the steel

structure operation.In this case, it is necessary to carry out

specialized management for the participants of steel structure

projects.In the actual management of steel structure project

participants, it is found that the actual management work often

fails to achieve the expected effect.Firstly, due to the uneven

level of professional knowledge and comprehensive quality of the

construction personnel involved in steel structure construction,

they are not specialized steel structure construction

personnel.Secondly, there are many problems in the management of

steel structure construction personnel.The employees have loose

attitude and poor discipline, which is not easy to be managed in a

unified way.Facing this problem, the construction unit should

formulate a corresponding management system to restrain them, and

should not use conventional management methods.In addition, the

pre-service education and training of employees should be

strengthened to give full play to the enthusiasm of employees so

that they can naturally comply with the rules and regulations.

2, improve the construction control mechanism

In the process of engineering construction, more attention should

be paid to the construction of construction quality control

mechanism, to ensure the overall quality of engineering

construction by perfecting the construction mechanism.First of all,

the relevant units should improve the existing construction quality

management mechanism, combine the problems that may occur in

different construction links, and establish corresponding

management and processing mechanisms.Secondly, pay attention to the

construction supervision of steel structure.In the process of steel

structure construction, many different types of problems may be

encountered, and the corresponding processing mechanisms may be

different.In order to save the construction time and reduce the

construction difficulty, some construction personnel may adopt

unreasonable construction methods in the construction process, but

these methods cannot meet the construction requirements.Under the

supervision of the supervisory unit.All the work can be carried out

scientifically and reasonably, the probability of non-standard

construction problems is greatly reduced, and the overall quality

of the steel structure can be effectively guaranteed.The

construction party should establish a sound supervision and

management mechanism, encourage the relevant construction personnel

to supervise each other, cultivate their sense of crisis and

rigorous work attitude, and ensure the rationality of construction.

3,Strengthen construction material management

The quality of materials is directly related to the construction

quality and is an important content of construction quality

control.In the construction of steel structure project, the cost of

steel structure material is very high.Strengthening the

construction material management reduces the construction cost

while ensuring the subsequent steel structure construction

activities are carried out in an orderly manner.This requires

comprehensive consideration of construction needs and selection of

high quality and inexpensive materials.Specialists conduct in-depth

market research, compare and analyze the materials, lay the

foundation for more orderly implementation of subsequent steel

structure construction activities, and effectively improve the

construction quality of steel structure projects.

4,Strengthen the quality control of on-site steel structure

components

At the same time, the quality control of on-site steel structure

components should be strengthened.First of all, check the samples

provided by the permanent representatives and supervisors.If any

problem is found, the factory should be notified at one time for

correction and to ensure the quality of steel structure components

can be transported.On the other hand, the steel structural members

need to be inspected by the quality inspector of the supervisory

unit upon arrival at the site.

transport

FAQ

1. Are you manufacture factory or trading company?

We are manufacture factory, located in Qingdao city, near to

Qingdao port. And we have total 7 workshops from steel structure to

wall and roof sheet.

2. Can you provide free design?

Yes, we have 10 senior engineer with rich experience. You only need

to give me youridea, we will design for you with free.

3. Can you offer competitive prices?

If you have no special requirement for the material, we all use

materials from big material manufacture companies. We also can

design it according to your requirement. But no matter what kind of

quotation mode, offering the reasonable

price is our business objective.

4. How to install? Can you provide engineer to help?

We will provide the detail installations , like the CAD, 3D tekla,

etc. Or we will provide the engineers to help according to your

requirement.

5. Can I have a visit to your factory before the order?

Why not? Welcome to visit our factory. You can fly to Fujian

Quanzhou Airport, then we will pick you up at the airport, hotel

booking service is available.

6. ls your price competitive compared with other companies?

A:Our business objectives are to give the best price with same

quality and best quality with the same price. We will do everything

we can to reduce your cost and guarantee you get the best product

that you paid for.

7. Do you accept container loading inspection?

A:You are welcomed to send an inspector, not only for the container

loading, but any time during theproduction time.

8. Do you offer designing service for us?

A:Yes, we could design full solution drawings as your

requirements.By using Auto CAD,PKPM ,3D3S,Tekla Structures (X

steel) etc., we can design complex industrial building like office

mansion, super marker, auto dealer shop,shipping mall, 5 stars

hotel.

9.What is the delivery time?

A:Delivery time depends on order quantities.In general, the

delivery time to nearest seaport in China will be 30 days after

receiving deposit.

10.How can you get a quotation for your projects?

A:You can contact us by email, phone, TM, WhatsApp and so on 24*7

and you will get reply within 8 hours. Firstly, please send us your

project details and your requirements. Then we will design

accordingly, free of charge.Afterwards, please check and confirm

whether you like the drawings. If not, we shall get the drawings

revised until your confirmation.